Organic Light Emitting Diodes (OLEDs)

Organic light emitting diodes (devices) or OLEDs are monolithic, solid-state devices that typically consist of a series of organic thin films sandwiched between two thin-film conductive electrodes. When electricity is applied to an OLED, under the influence of an electrical field, charge carriers (holes and electrons) migrate from the electrodes into the organic thin films until they recombine in the emissive zone forming excitons. Once formed, these excitons, or excited states, relax to a lower energy level by giving off light (electroluminescence) and/or unwanted heat.

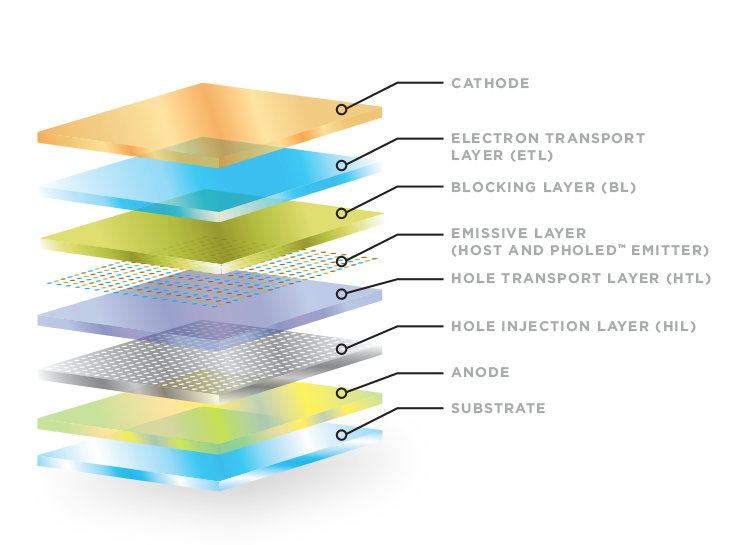

The basic OLED cell structure consists of a stack of thin organic layers sandwiched between a conducting anode and a conducting cathode. Breakdown of an OLED structure:

Substrate (can be plastic, glass, or metal foil) – Foundation of the OLED

Anode (may or may not be transparent depending on the type of OLED) – Positively charged to injects holes (absence of electrons) into the organic layers that make up the OLED device

Hole Injection Layer (HIL) – Deposited on top of the anode this layer receives holes from the anode and injects them deeper into the device

Hole Transport Layer (HTL) – This layer supports the transport of holes across it so they can reach the emissive layer

Emissive Layer – The heart of the device and where light is made, the emissive layer consists of a color defining emitter doped into a host. This is the layer where the electrical energy is directly converted into light.

Blocking layer (BL) – Commonly used to improve OLED technology by confining electrons (charge carriers) to the emissive layer

Electron Transport Layer (ETL) – Supports the transport of electrons across it so they can reach the emissive layer.

Cathode (may or may not be transparent depending on the type of OLED) – Negatively charged to inject electrons into the organic layers that make up the OLED device.

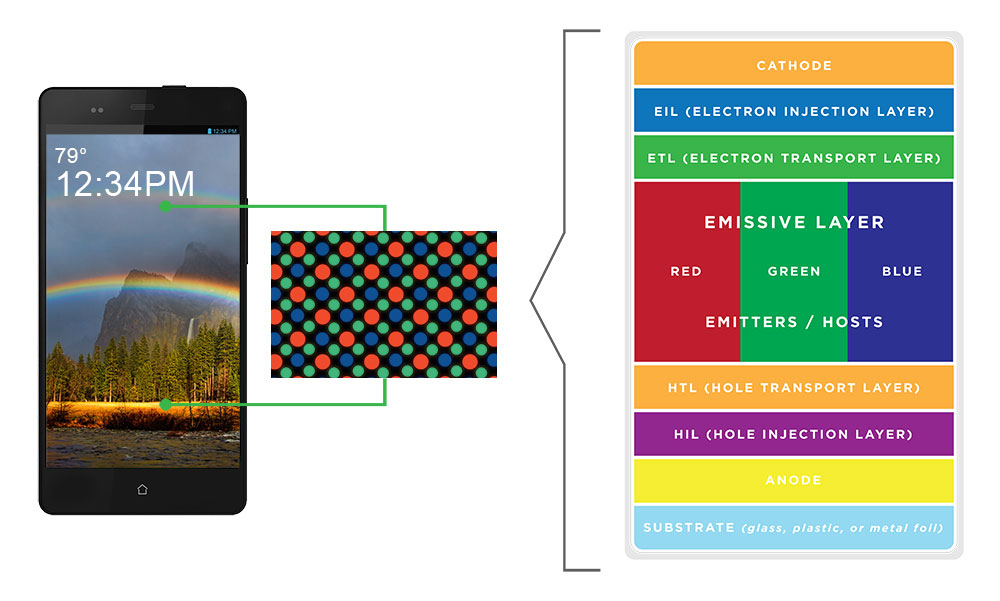

To generate red, green and blue light to render full-color images, there are two main approaches currently being used. The first is to pattern red, green and blue OLED sub-pixels in each pixel of the display, as shown below. This is generally the preferred approach for high-resolution mobile displays.

RGB OLED side-by-side

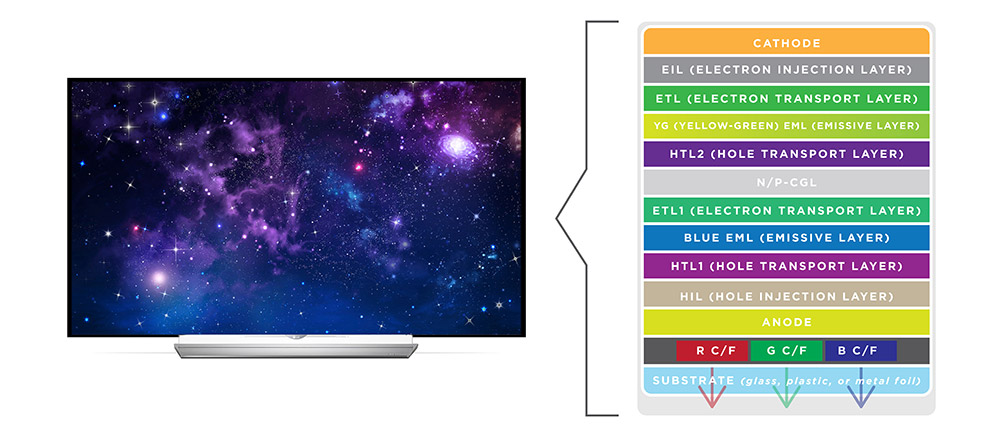

The second approach is to produce white light in every pixel, and then use a color filter to make red, green and blue sub-pixels.

White OLED with Color Filter (CF)

OLED displays including TVs, smartphones, wearables, IT and VR

Gestant Display Technology Co.,Ltd. could provide a series of LCD and OLED products, such as AMOLED Screen, PMOLED Screen, Round Display Screen, Flexible Display Screen, TFT LCD, Mono-LCD and Bar Display Screen. Customize PCBA/LCD/OLED/FPC/Backlight/Coverlens/TP solutions.

About Gestant Display

Gestant Display Technology Co.,LTD was founded in 2012 in Shenzhen China. Even, the founder of the company, has more than 15 years of rich experience in LCD display industry. He has been engaging in the basic research of LCD display technology in Japan since his graduate school and has been working in the flat panel display industry after graduation.

Proficient in the manufacturing process and technology development of LCD / OLED / polarizer, Even was also one of the members of China liquid crystal Association who has a senior industry background and supply chain resources. In the past three years, he assisted his shareholders in building factories, purchasing equipment,establishing production lines, and successfully obtaining ISO9001 and ISO14001 system certificates.

He has established good business relations with major panel manufacturers in China (BOE /Tianma / IVO /EDO / Visionox), and the glass supply is stable and sufficient.

Gestant Display's products are widely used in Smart wear,Smart home,Outdoor photography,IP phones, Medical care, Industrial control equipment, Automotive and Vehicle displays, Instrumentation, and other Information terminal applications which could offer long-term after-sale services(such as 2 years quality warranty, long-term supply) .